Table of Contents

Applying solder mask to PCBs

Prerequisites

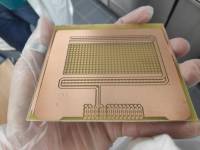

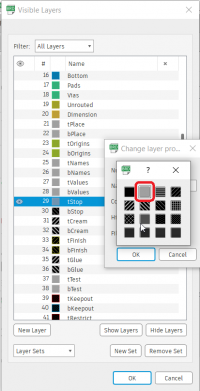

This instruction is about how to apply solder mask to PCBs. It is assumes you already have traces on a PCB (regardless of etched or milled) but no holes yet, like figure 1. You also need artwork (black printout to transparent foil) containing only pads and vias. You can achieve this by selecting “tStop” (layer 29) or “bStop” (layer 30) for top and bottom respectively. Make sure to select a solid fillstyle (see figure 2).

The room you are working in has to been protected from of UV lights, e.g. use 05 EG 027. It has special lamps and no windows (avoiding sunlight).

Procedure

- Put on gloves to avoid fingerprints.

- Clean your PCB (using alcohol based solutions, e.g. ethanol).

- Remove the cover from the laminator (figure 3).

- Heat up the laminator and wait for it to reach 115°C. Do not touch the orange/red rolls.

- Laminate. The result may look like figure 4

- Turn off the heat to the laminator

- Check the the PCB for air bubbles. The solder mask will later break at these points after curing. If neccessary you can use the development solution to strip of the laminate completely.

- Chill PCB with cold water. (Necessity of chilling is questionable.)

- Align the artwork to your PCB and tape it.

- Expose it with UV light for 60 seconds (setting 1|0|0). You should wait for the vacuum to build before you start the exposing.

- Take out the PCB and wait for 5 minutes. (Necessity of waiting is questionable.)

- Remove the second protective foil (on the shiny sides).

- Cut of excessive laminate.

- Put on your other personal protective equipment (goggles, lab coats).

- Set up development solution, leftovers from etching process can be used. Normal developer would be 5g sodium hydroxide in 250 ml (purified) water. Lower concentrations lead to longer developing times, which can be beneficial for better handling.

- Develop for 60 seconds (assuming new strong solution). Look out for color changes. The pads/vias should become turquoise.

- Remove solder mask on pads/vias mechanically with toothbrush.

- Rinse PCB with (purified) water and wait for 5 minutes. (Necessity of waiting is questionable.)

- Dry the PCB for example by feeding it again multiple times through the hot laminator but covered with baking paper.

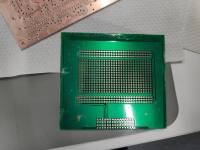

- Complete the curing of the solder mask by exposing it further for 20-30 minutes or leaving the PCB at a place with sunlight for a day (figure 5).

- Turn off the laminator and put the cover back on (check temperature before you do that).

- Go on like in a usual PCB manufacturing process (drill holes, punch via, solder).

Fig. 1: Etched PCB

Fig. 1: Etched PCB

Fig. 2: Layer 29 / Fillstyle setting

Fig. 2: Layer 29 / Fillstyle setting

Fig. 3: Dry-film laminator

Fig. 3: Dry-film laminator

Fig. 4: Laminated

Fig. 4: Laminated

Fig. 5: Finished

Fig. 5: Finished